|

|

|

|

Exterior Insulation improves

performance

of steel framed structures |

|

Recognizing that structures built with steel framing, cavity insulation and brick veneer exterior claddings were increasingly subject to moisture-related ailments, the Canadian Mortgage and Housing Corporation decided to try and determine the causes of these problems and further, how to mitigate them. Recognizing that structures built with steel framing, cavity insulation and brick veneer exterior claddings were increasingly subject to moisture-related ailments, the Canadian Mortgage and Housing Corporation decided to try and determine the causes of these problems and further, how to mitigate them.

Condensation was accumulating in the wall cavity, leading to deterioration of the studs, sheathing, brick ties, and insulation. Moisture in the brick was not uniformly distributed and was sufficient enough to affect the cladding adversely in freeze/thaw cycles.

The wet insulation and sheathing fostered mold growth and reduced interior air quality.

Walls designed to last 50 years were deteriorating in a much shorter period of time.

This study, entitled "Performance of a Brick Veneer/Steel Stud Wall System" examined the relationship between framing, insulation and cladding - and how these can be designed to perform better when used together in real world conditions.

It was theorized by many experts that thermal bridging at the studs in addition to heat lost due to air leakage compromised the thermal resistance of such wall assemblies, and the CMHC verified this by evaluating "perfect" test walls built in strict accordance with all Codes and standards, and observing similar results.

A key conclusion of their research is that by placing sufficient insulation on the exterior of the sheathing, the dew point temperature would not fall within the wall cavity - reducing thermal bridging and the condensation that occurred on the studs as a result! Dryvit Engineering services can provide a free water vapor transmission (WVT) analysis for any building design to confirm this.

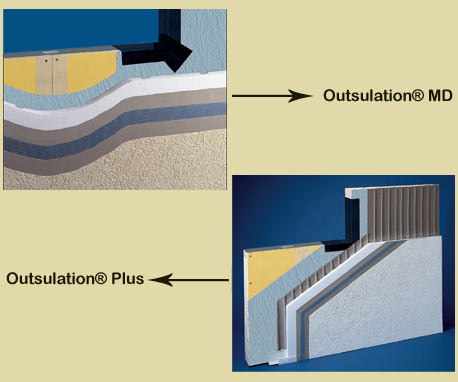

Dryvit Outsulation Systems place insulation on the exterior of the wall, reducing air leakage and eliminating thermal bridging in steel framed construction. As steel framed construction continues to gain market share, the issues of thermal bridging, pressure equalization, condensation and moisture must be addressed when considering the building design - and Dryvit Outsulation systems offer cost effective, efficient design solutions to these challenges.

Dryvit Outsulation systems offer other meaningful benefits, such as:

-

Unmatched energy efficiency.

Dryvit Outsulation systems were found by the Oak Ridge National Laboratory to be at least 84% more energy efficient than other tested claddings.

-

Incredible design flexibility.

Dryvit offers a wide array of acrylic based finishes which accurately replicate many types of materials - stucco, cement, limestone, granite and even brick - allowing you to have the look you want and a more energy efficient exterior.

-

Lighter weight and faster to install.

Dryvit Outsulation systems weigh a fraction of heavier claddings - allowing for potential savings in footings and structural steel, as well as on construction time itself.

Dryvit systems are the perfect compliment

to steel stud construction!

|

|

A New Way to "Energize" Your Building Exterior |

|

Dryvit Outsulation® systems meet the energy requirements of the Massachusetts State Building Code

Dryvit Outsulation systems have always been known for the extraordinary energy efficiency they offer to design professionals and building owners alike. Now those energy advantages take center stage in Massachusetts, where new energy conservation requirements (Massachusetts State Building Code - 780 CMR 13 and 14) govern construction. Dryvit Outsulation systems have always been known for the extraordinary energy efficiency they offer to design professionals and building owners alike. Now those energy advantages take center stage in Massachusetts, where new energy conservation requirements (Massachusetts State Building Code - 780 CMR 13 and 14) govern construction.

Importantly, Dryvit Outsulation systems conform to the revised Energy Code in two significant ways:

-

Backstop NT™ meets the recently revised Chapter 13 requirements for exterior envelopes, including updated requirements for continuous air barriers.

-

In addition, all Dryvit Outsulation systems have been evaluated to meet requirements of the International Code Council (ICC) as an appropriate "Exterior Wall Covering" and also meet the requirements of Chapter 14 of the revised Massachusetts code.

These important developments strengthen the already compelling argument for specifying Dryvit products and systems on your next Massachusetts building project. Perhaps most significantly, similar energy standards are under consideration for implementation in several other states, and eventually may become the standard around the country.

Dryvit Outsulation Systems conform to

the MA Energy Code Standards

There are several pertinent sections of the revised Massachusetts State Building Code that highlight

Dryvit's compliance with the new energy standards:

Chapter 13 - Energy Conservation

(Section 1304.1.2 Moisture Control)

Requires that vapor barriers equal to 4-mil polyethylene be installed on the

winter warm side of the wall. Dryvit's Water Vapor Transmission Analysis - available to all design professionals - helps you assess conformance to the standard, as well as identify noted exceptions to the standard.

Chapter 13 - Energy Conservation

(Section 1304.2 Prescriptive Building Envelope Criteria)

With the exception of wood framing, the new code also requires continuous insulation with R-values ranging from R3 to R7 (1"-2" of EPS). Metal framing requires R11 or R13 Batts.

Chapter 13 - Energy Conservation

(Section 1304.3 Air Leakage)

Air permeability cannot exceed .004 CFM/ft2 at 1.57 PSF. Dryvit Backstop NT™ complies with the standard. Both are able to withstand design loads such as wind, stack pressure and mechanical pressure without damage or displacement, are continuous with all joints are airtight and do not create conditions that will deteriorate building envelope components.

Chapter 14 - Exterior Wall Coverings

(Section 1403 Performance Requirements)

Dryvit Outsulation systems meet performance requirements such as durability, weather resistance, structural and fire performance. All Dryvit systems are tested in accordance with an Acceptance Criteria for EIFS that is published by ICC ES that include all of these criteria.

For more information on how Dryvit Systems comply with the new Massachusetts State Building Code contact Dryvit Systems at 1-800-556-7752, or contact your local Dryvit Distributor. For information on system specifications and details, visit our web site at www.dryvit.com.

|

|

|

|

|

|

|

|

|

|

|

|

Heating and Cooling

Heating and cooling account for about 56% of the energy use in a typical U.S. home

Click for more...

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Dryvit Reducing Energy Use

By the end of this year, Dryvit Systems Inc. plans to have uniform policies and procedures in place to recycle paper, cardboard, batteries and light bulbs at each of its five North American locations.

Click for more...

|

|

|

|

|

|

| |

|

|